GP VOID VENT

GP® VOID VENT is a geocomposite void former composed of a cuspated High Density Polyethylene (HDPE) Drainage core with a non-woven polypropylene (PP) geotextile separator/filter bonded to one side. Optimised for maximum strength and performance, providing high levels of air/gas flow.

Read MoreProduct Benefits

- HDPE does not support bacterial growth.

- HDPE is highly resistant to acids and alkalis.

- Made in accordance with the recommendation contained within NHBC Guidance and BS8485:2015 + A1 2019.

GP® VOID VENT is a cuspated HDPE core with a geotextile filter/separator bonded to a single side, in either 25 mm or 45 mm depth. The intended use of the void vent is to provide a means of ventilation when used in conjunction with an approved gas protection barrier, in accordance with the recommendation(s) contained within NHBC guidance and BS8485:2015 + A1 2019.

The Void Vent is supplied in either 25mm or 40mm void depth. Material is joined by overlapping of the loose edge of geotextile for full coverage, or laid in strips as per the ventilation design.

Complies with the latest codes of practice as published by BRE, CIRIA and NHBC. Void Vent is independently tested and verified by UKAS accredited bodies.

| GP® VOID VENT 25 mm | GP® VOID VENT 40 mm | |

|---|---|---|

| Color | Black | |

| White | ||

| Material | Polyethylene - High Density Polyethylene (HDPE). | |

| Size | 0.9 x 50 m x 27 mm | 0.97 x 25 m x 42 mm |

| Uniclass 2015 | Pr_25_57_51_74 | |

| CAWS | D21/360 Geocomposite venting layers |

| GP® VOID VENT 25 mm | GP® VOID VENT 40 mm | |

|---|---|---|

| Standard | BS 8485: 2015, A1 2019. | |

| Material | ||

| Studded layer | High-density polyethylene (HDPE). | |

| Filter layer | Geotextile. | |

| Sheet thickness | 27 mm. | 42 mm. |

| Weight (minimum) | 60 kg. | |

| Performance characteristics | ||

| Flow rate | 5 l/m/s. |

| Characteristics | Test Method | GP® VOID VENT 25 mm | GP® VOID VENT 40 mm |

|---|---|---|---|

| Thickness | EN ISO 9863-1 | 27 mm | 42 mm |

| Material Design | N/A | ||

| Roll Width | N/A | 0.9 m | 0.97 m |

| Roll Length | N/A | 50 m | 25 m |

| Gross Roll Weight | N/A | 60 kg | 50 kg |

| Product Information | |||

| Polymer | High Density Polyethylene | ||

| Biological Resistance | HDPE does not support bacterial growth | ||

| Chemical Resistance | HDPE is highly resistant to acids and alkalis |

| Characteristics | Test Method | GP® VOID VENT 25 mm | GP® VOID VENT 40 mm |

|---|---|---|---|

| CBR Puncture Resistance | EN ISO 12236 | 1.4 (-0.14) kN | 1.4 (-0.14) kN |

| Tensile Strength (MD/CMD) | EN ISO 10319 | 20/15 (-2.0/-1.5) kN/m | 10/10 (-1.0/-1.0) kN/m |

| Compressive Strength | EN ISO 25619-2 | 300 kPa | 200 kPa |

| Characteristics | Test Method | GP® VOID VENT 25 mm | GP® VOID VENT 40 mm |

|---|---|---|---|

| Pore Size (O90) [geotextile] | EN ISO 12956 | 80 (± 20) μm | 80 (± 20) μm |

| Permeability (H50) [geotextile] | EN ISO 11058 | 100 (-20) l/m2/s | 100 (-20) l/m2/s |

| Water Flow Capacity [Composite] (200 kPa, (i)=1) | EN ISO 12958 | 5 l/m/s | >5 l/m/s |

| Gas Flow Capacity [Composite] | Calculated (a) | 0.024 m3/s | 0.033 m3/s |

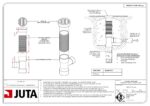

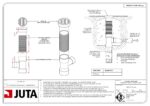

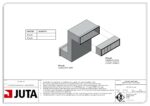

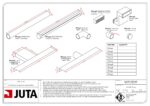

GP® VOID VENT is designed to be used below ground level structures to provide a void in which harmful gases have a preferential pathway to flow through the underside of the building and discharge at the perimeter via suitable outlet accessories dependent on the design.

GP® VOID VENT should be used in conjunction with an approved Gas Protection Barrier and in accordance with the recommendations contained within BS8485:2015 + A1 2019.

Gas venting design should be prepared by a suitably qualified geo environmental engineer with calculations to demonstrate suitable dilution capabilities. JUTA UK recommends the installation of the GP® VOID VENT is completed by a suitably qualified and accredited installers (NVQ level 2). JUTA UK can offer advice as to suitable/recommended installers if required.

A selection of standard details for information and education purposes only. Note - it is strongly advised appropriately qualified, and insured personnel undertake gas membrane installs. A gas membrane performs a critical function in the application setting and has an anticipated design service life in excess of 60 years. Do not attempt to install gas membranes from these details alone. Sole rights for use and distribution are owned by JUTA UK LTD.

Ground Vent Box

Telescopic Vent

Roll weights can be between 50 kg and 100 kg hence appropriate equipment is required for unloading and handling.

GP® VOID VENT is supplied in packaging designed to protect the product from damage during handling and storage, and degradation as a result of UV exposure. GP® VOID VENT should be kept in the supplied packaging until such time as it is required for installation.

Get In Touch With The Experts

If you feel first class service, premium products direct from source, and bespoke solutions are right for you then don't hesitate to contact our team today on 01772 754177 or email us at [email protected]

Contact Us